A big part of my job involves working on Process Improvement projects for our transplant program.

There’s this tool that is used in PI work called the “5 Whys” that is meant to help identify the root cause of a problem. Some of you may have heard of this!

I’ve been meaning to share about this for a while, in case you hadn’t heard of it, because I think it’s just such a nifty tool. Not only for work related things, but in any facet of life.

The gist of it goes: You identify a problem. Then, you started asking “why” over and over until you can’t anymore. At that point, you should have hopefully arrived at the real, or root, cause of the problem.

Very simple, yet very effective. It can help cut through all the “noise” and help you zoom in on what is actually going on.

It’s best seen in action…. ->

Typical example used to teach this:

Problem: I got a speeding ticket.

Why? I was late for work.

Why? I woke up late.

Why? My alarm didn’t go off.

Why? It wasn’t turned on.

Why? I forgot to check my alarm last night.

Root cause: Not remembering to check and turn her alarm on.

Possible solution? Set a recurring alarm, set a reminder, pair “turning on alarm” with brushing teeth before bed, etc. (Solution picking is a whole other arm of Process Improvement that has its own methods!)

If you just set out to fix the problem (getting a speeding ticket) without understanding the root cause, you might just say, “Well, I need to drive more slowly”. Yes, true, but then you’d still be late for work, and you still overslept, and all the rest. You aren’t really addressing the REAL problem, so this problem will occur again…. and again… and again. If you address the root cause, though, it will naturally impact everything upstream, and you’re more likely to just eliminate the issue altogether! That’s the goal.

Let’s do a couple more. 😁

A medical example

Problem: A patient received the wrong medication.

Why? The nurse picked the wrong vial from the cart.

Why? The labels were similar and hard to distinguish.

Why? The pharmacy department used a generic label.

Why? They didn’t have the specialized labels.

Why? The supplier changed labeling format but the hospital didn’t adjust their practice accordingly.

Why? There’s no protocol in place for updating the label standards when the supplier changes.

Root cause? No standard protocol for how/ when to update the med labels

Solutions? Create and adhere to a policy!

(*This is merely a made up example and is not representative of anything that actually occurred at my institution.)

A business example!

Problem: The monthly report wasn’t delivered to the client on time.

Why? It wasn’t finished on Friday.

Why? The data from the finance team came in late.

Why? They didn’t know the report was due that day.

Why? The reporting calendar was never shared with them.

Why? There’s no formal process for communication across departments.

Root cause? No cross- functional communication plan for recurring deadlines

Solutions? Create a shared calendar with automatic reminders for deadlines.

This could also totally be applied in regular life, or when trying to figure out why something isn’t working.

A parenting example:

Problem: My kids never eat their dinner.

Why? They say they aren’t hungry.

Why? They ate a big snack too close to dinner.

Why? When we got home after school, dinner wasn’t ready yet but they were starving.

Why? They hadn’t eaten since lunch at 12:00.

Why? There’s no afternoon snack at school, and I didn’t pack snacks for the drive home.

Root cause? They have no snacks to eat earlier on the way home in the car.

Solutions? Pack snacks for the car so they can snack sooner and not so close to dinner time.

Get the idea?? I really like this tool! It seems so obvious once you do it, but root causes are not actually always obvious at first. It’s just easy to sort of…. overlook them. Using the 5 Whys can help peel back the layers.

This process can bring clarity to a situation and also can lead to some simple yet effective changes.

I was using it to think through my morning routine. I often feel like I sort of squander away too much time in between my alarm going off and being dressed and able to start doing something I actually want to do.

Problem: It takes too long between my alarm going off and being down at my desk.

Why? I lay in bed after my alarm goes off.

Why? I’m looking at my phone.

Why? Because I grab it to turn my alarm off and then start scrolling.

Why? It’s in my room at night and I don’t have another alarm.

Root cause? Keeping my phone by my bed as an alarm leads to me getting up later than desired.

Solutions? Use a different (non-phone) alarm. Don’t keep phone in bedroom. Keep phone in bathroom instead of nightstand. Etc.

Has anyone ever heard of this or used it? Let me know if you try it. 🙂

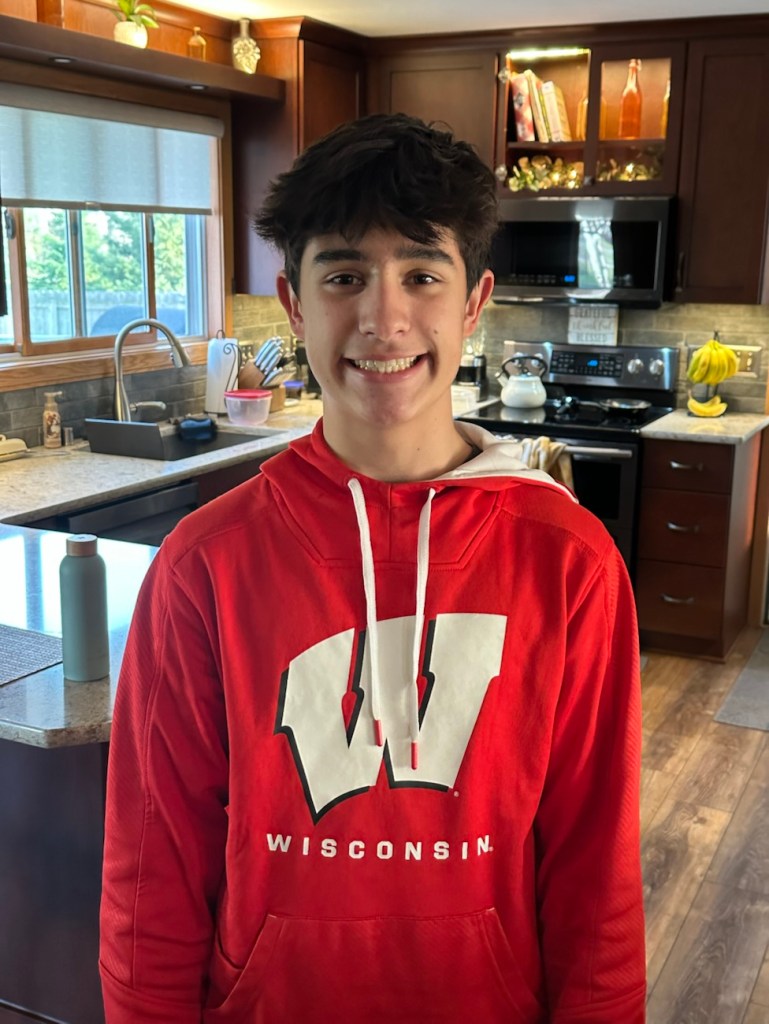

Daily Gratitude: I am grateful for Ethan getting his braces off yesterday!! He got them put on in September 2022 when he had just turned 14. Now’s he’s 16.75 and has changed so much.

Here he is: pre-braces, with brand new braces, and finally….April 2025, no braces!! 🙂

I think this technique was highlighted on a podcast I listen to recently but I can’t recall which podcast! Or if I read it somewhere? My brain is fried these days. It caught my attention because it reminded me of a Bluey episode where the dad kept asking why over and over to get to the root cause but then Paul thought it would be funny to just use it in general and ask why a ridiculous number of times until we lost our minds. Lol.

But I will keep this in mind next time I have a problem to solve! Love the pics of Ethan! He has changed so much!!! He looks like a kid in the first pics but def looks like a teen in the post-braces pic.

LikeLike

Yes, I have used the “5 Whys” tool in the past, Kae. I’ve also used a tool called the “Lean Manufacturing Principles” or “Lean Production Principles” in the factories that I used to worked at, so I know that the “5 Whys” tool is a part of the Lean Manufacturing Principles which together are developed by the Toyota company. I know that I still make things nowadays, so in principle, the Lean Manufacturing Principles still apply to me today.

This occurred years ago, but when I started to physically exercise as a habit, it can be attributed to the “5 Whys”.

LikeLike

I think I do that all the time quickly and intuitively. sometimes I don’t like the answer, sometimes I don’t have solution to the bottom line, but goood to know the root cause and either do the solution or accept the problem 🙂

LikeLike

This is a great strategy! I love the examples you shared, too. I don’t think I have ever implemented this strategy intentionally but it seems really helpful.

LikeLike

I have done this before. I remember the first time I heard about it – in Time Ferris’ Tools of the Titans (or was that the title). I found it so helpful at the time.

I can’t wait until our daughter gets her braces off.

Correction, I can’t wait until we stop having ortho payments! We’ve been so fortunate the whole experience has gone extremely smoothly (it’s actually be a lot less onerous than I expected), but it will be nice for her to not have to contend with braces. I do wonder how faithful she’ll be about wearing her retainer and I know when kids lapse in that, all the THOUSANDS in ortho adjustments can go out the window (I feel like that’s what happened to SHU?). We shall see.

LikeLike

This is fantastic! I’m going to share this with my team at work. We just came out of a summit where we talked about all sorts of process/client issues we’ve been having and I think this would really help us nail down the PROPER process we need.

I can also see how useful it is for personal use and habit formation. Although I don’t think I’d like the answer to the question, “Why can’t I get to bed at a decent hour?” SIGH.

LikeLike